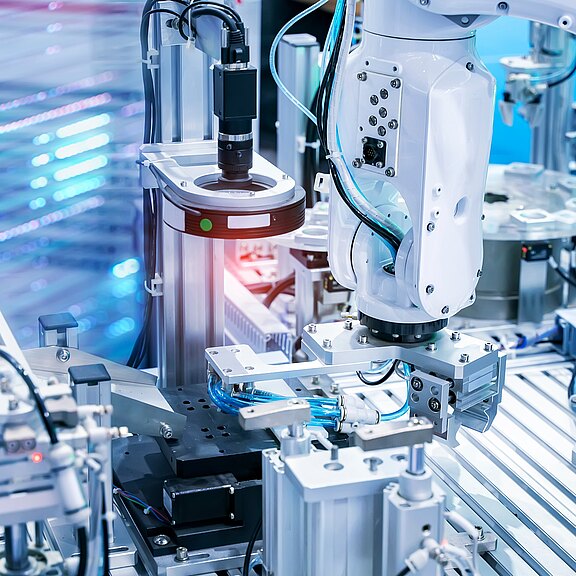

Solutions for Mechanical Engineering - Explosion Proof Cameras In Manufacturing

Safety in production environments

SAMCON offers innovative safety solutions for mechanical engineering and industrial production. Our explosion proof cameras and hazardous area lighting systems are designed to maximize workplace safety in demanding manufacturing environments without compromising performance. From monitoring filling and dosing systems in hazardous areas where alcohols or vegetable oils are processed, to providing reliable illumination at critical points, we deliver solutions that meet the highest international safety standards. ATEX certified cameras for production facilities, IECEx certified IP cameras for hazardous zones, and Class I Division 1 and 2 CCTV systems ensure safe and efficient operation in sensitive industrial areas.

Industrial Applications

Explosion proof CCTV systems provide reliable video monitoring of production areas to enhance plant and worker safety. In continuous mixing processes or during machinery downtime, Ex cameras deliver real-time images that allow operators to respond immediately to abnormal situations. Thermographic cameras support non-contact temperature measurement on rotating machine components, enabling early detection of friction, bearing failures or overheating. Stainless steel housings with IP66 and IP68 protection ensure corrosion and chemical resistance even under extreme industrial conditions.

SAMCON’s ExCam series is ideal for automated manufacturing cells. Explosion proof cameras for industrial image processing support inline inspection of surfaces, barcodes or positional data without human intervention. Compact miniature cameras with ATEX certification can be easily integrated into confined machine housings, such as lubrication or adhesive systems. In painting and cleaning robots, compact explosion proof cameras deliver real-time feedback for mobile use in hazardous zones. At chemical dosing units, Ex cameras connected to PLC and SCADA systems provide visual process feedback for leaks, pumps or tank levels, ensuring safety in hazardous manufacturing environments.

Technology and Integration

Our explosion proof camera systems are engineered for simple and flexible integration into existing automation architectures. The one-cable solution simplifies installation of miniature cameras in tight spaces, while stainless steel enclosures ensure durability in aggressive environments. Thermographic solutions enable reliable process monitoring by capturing temperature variations in real time. Explosion proof cameras for industrial automation thus combine process safety, compliance with ATEX, IECEx and Class/Division standards (in progress), and seamless integration into production control systems.

Why SAMCON?

SAMCON provides certified explosion proof cameras and lighting solutions for mechanical engineering and manufacturing industries. With approvals including ATEX, IECEx, Class I Division 1 and 2 (in progress), INMETRO, PESO, EAC-Ex, UKEX and MASC, our systems are built for global use in hazardous industrial environments. Designed for automated production lines and flexible integration, they support safe and efficient manufacturing processes while reducing risks for both personnel and assets.

SAMCON solutions enable manufacturers to enhance operational safety, comply with international explosion protection standards and optimize production efficiency with robust and durable hazardous area camera systems.

Check us out! Get in touch with us or simply contact us by e-mail!