World`s smallest explosion proof spot-finder thermographic camera

Thermal imaging camera with auto-focus and infrared thermometer

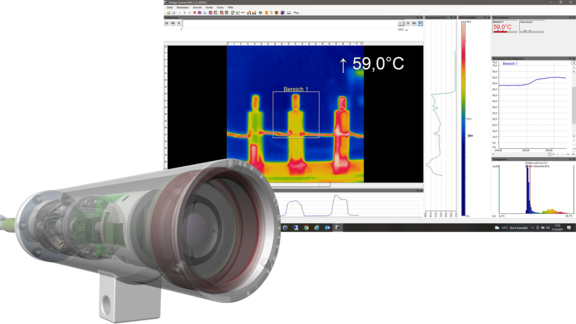

The ExCam XI80 is a powerful thermographic camera with an integrated infrared thermometer and auto focus for use in potentially explosive areas. It delivers excellent infrared images (80x80p) in a temperature range from -20°C to 900°C. In addition, the thermal imaging camera has extensive analysis functions (e.g. thermal analysis with hot and cold spots). The Excam XI80 can not only see where it is hot, it can also measure the temperature exactly; and all that in an 8 millisecond interval (Real Time Recording). Like all cameras in the ExCam series, it is certified according to European regulations (ATEX) as well as international ones (IECEx). These certificates and further documents can be found in the download area.

Features.

- Certification for Hazardous Areas (ATEX & IECEx)

- Ultra-Compact and Leightweight Thermal Imaging Camera with integrated IR-Thermometer

- Thermal Technology with 80x80p Resolution

- Exact Temperature Measurements from -20°C to 900°C

- Thermal Sensitivity NETD 0.1°C

- Imager with Motor-Focus

- Optical Resolution with Distance-to-Spot-Size Ratio up to 190:1

- Different Optics available (Standard, Tele, Wide)

- Autonomous Operation with Automatic Spot Finder

- Single-Cable-Solution (Ethernet, Voltage, I/O)

- Protection Level of IP68/IP66 (IEC 60529)

- Extensive Accessories

Rugged thermal camera with ATEX and IECEx-certification

Besides the European regulations (ATEX), the ExCam series is also certified according to international regulations (IECEx). The housings’ certification comprises ATEX group II (Gas and Dust) for zone 1, 2 as well as 21 and 22 including the explosion groups IIC / IIIC with a high risk of mechanical threat. In addition, certification can be extended at any time to cover different markets.

During the ExCam XI80’s development stage the focus was clearly laid on security aspects as well as mechanical precision and high-quality stainless steels. In addition, the modular design of the housing components prior to the camera’s development allows a free combination of the individual housing components such as different flanges in combination with the housing body - without any limitations regarding explosion protection.

Various Applications for Thermography Ex-Cameras / Where are thermal processes used?

Ex-proof thermal cameras can be used for various applications in electronic, aerospace industrie, plastics, mechanical- and chemical industries, completely independant from lightning conditions. In addition to time, temperature is the most frequently measured physical property. Temperature behavior is often a good indicator of the condition of physical systems. Friction generates heat, resistances of electrical contacts increase the temperature; Energy losses are often reflected in changes in temperature. For this reason, thermal processes are used in almost all branches of industry:

- Research and development (electronics development, test stands, solar panel industry, development of LCD flat screens, ...)

- Test stations

- Process automation (plastics industry, flat glass production, metal, surface technology, detection of hot spots in bulky materials on conveyor belts, detection of exceeding a certain temperature, safety: avoidance of fire development, fire prevention, easy integration into automation thanks to software, ...)

- Portable measurement tasks for maintenance

What is the camera suitable for?

The ExCam XI80 delivers excellent infrared images of objects in a temperature range of -20°C to 900°C. The spot finder function enables exact temperature measurements without having to adjust the sensor again, as the sensor adjustment is carried out automatically. With the thermal analysis software, manufacturing processes can be constantly monitored and controlled, and production costs can be reduced through targeted process optimization.

Reliable Heat Monitoring / How does Temperature Measurement work?

The ExCam XI80 delivers a reliable detection any time of day and night. It sees even in complete darkness! The ExCam XI80 measuring IR camera uses an IR detector and a high quality lens. It combines the advantages of a pyrometer (IR thermometer) with those of an IR camera. The temperature is measured without contact. Physically, the pyrometer is based on the evaluation of the electromagnetic radiation emitted by the measurement object, which is proportional to the object temperature. The electromagnetic radiation is focused by the input optics and converted into an electrical signal by a corresponding infrared detector. For more details please refer to the booklet basic principles of non-contact temperature measurement.

The temperature limits of the ExCam XI80 are -10°C and 50°C.

Advantages of Non-Contact Temperature Measurement

- Extreme quick measurement

- Ultra long, continuous measuring ranges

- No influence on the measuring object

- Measurement on moving objects possible

- Measurement possible at high voltages and in aggressive media

Ultra-compact housing - thermal resolution

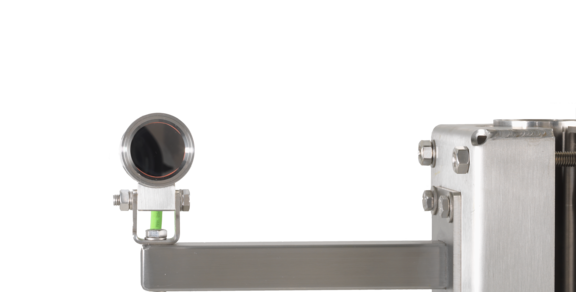

With its length of just 171.2 mm and a diameter of only 47 mm, the ExCam XI80 is as small that you can mount it everywhere. Thanks to the microbolometer the ExCam XI80 can deliver thermal images of moving objects.

Which field of view does the camera cover?

Thanks to different lenses it is possible to measure objectsat different distances. There are 4 different lenses available from which the customer can chose - depending on the requirements of the application: standard (55°), wide (80°), normal (30°) or tele (12°).

Distance Range for Thermography Camera / Size of measurement field and pixel

The recommended smallest target size is 2x2 pixels. The following table shows a relationship between the measurement object distance and the pixel size on the object level.

Media resistance and seals

Due to the high-quality materials used for the T07 Series, it is resistant against a lot of media. The particularly designed GYLON (PTFE) flat sealing does not only ensure the housing to be watertight (IP68) but also supports the resistance towards several chemicals. The extremely robust and scratch-proof as well as high-impact resistant germanium glass fits perfectly into the high-quality materials of the housing body.

The analyses software PIX Connect (optris)

There are no additional costs or license restrictions for the extensive analysis software optris PIX Connect. It is supplied with the camera and is compatible with Windows 7, 8 and 10. It also includes two software development kits (open source) for Windows and Linux. The user interface of the modern software is intuitive and can be individually adjusted to your specific application. There are several different layouts, various language options, measurement fields can be created as desired, maximum, minimum and mean values can be set. By setting the emissivity in different measuring fields, different material surfaces can also be measured with one camera. The measured values can be output as an image, diagram or digital display or saved for further analysis, video sequences can be saved with all temperature information for each individual pixel. For further information on the built-in module or the software, please visit the optris homepage.

Expansion of analog in-/outputs with industrial process interface (PIF)

The industrial process interface (external PIF) is a powerful expansion of the thermography systems. The expansion from the range of accessories is particularly recommended for applications with autonomous operation (no permanent connection to the PIX Connect software). The robust connection box meets the IP65 housing protection level, and a high isolation voltage (500 VACeff) between the camera and the process is also ensured. The permissible ambient temperature range within the non-Ex zones is -30°C…+85°C. The external PIF required an additional power supply (5…24 VDC)! The PIF device is compatible with the standard connection cable of the ExCam XI80 and expands the simple analog input and output to three analog inputs and outputs. Digital outputs are also available via the PIF. Communication takes place via an RS485 control interface and only has to be activated once via the PixConnect software. The user is then able to individually define three measuring fields, which are available on the process interface as 3x 4-20mA outputs. Furthermore, the main measuring field, internal temperature, flag status, alarms, fail-safe monitoring and many other functions can be assigned to the analog outputs. The PIF can be expanded by interconnecting 3 PIFs. A maximum of 9 analog outputs can be achieved with the cascade connection.

Accessories

Industrial Process-Interface

Questions about our products

If you have any questions about our products please contact our Sales Team.